We offer the most complete line of industry proven atmospheric plasma technologies to solve real world cleaning bonding coating and etching applications.

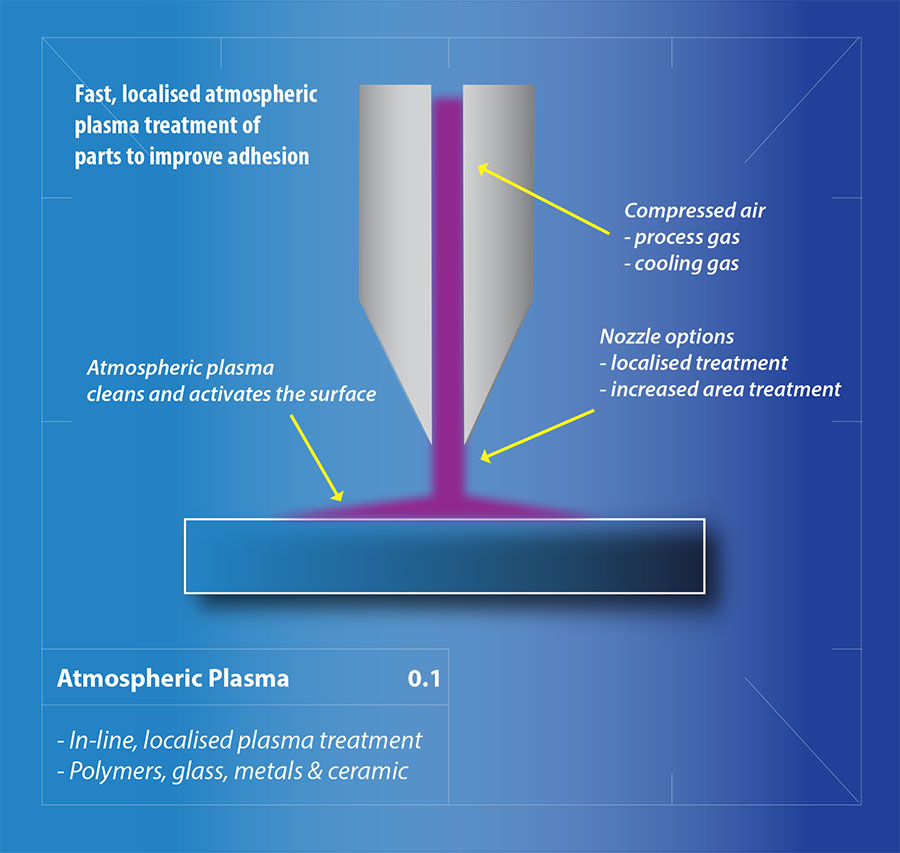

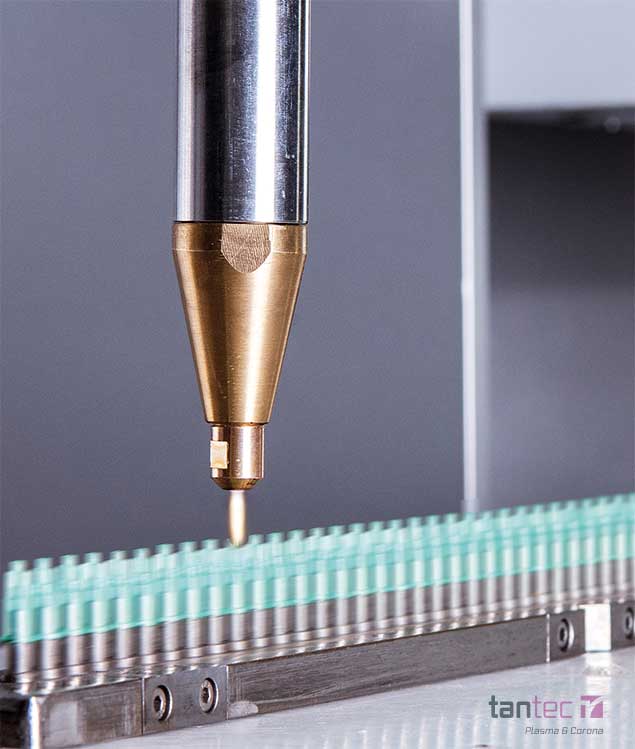

Atmospheric plasma treatment system.

It is designed to improve the adhesion of ink paint and adhesives prior to decoration coating or the joining of parts.

3dt s plasmadyne pro generates atmospheric plasma to treat a wide variety of materials used in manufacturing.

Atmospheric plasma treatment is ideal for in line processing or for the plasma treatment of small areas of larger parts that would otherwise be too large for vacuum batch processing.

And it s safer for your team and the environment.

The surfaceprep xd atmospheric plasma treatment system is thermal plasma offering a cost effective solutions for r d process development and full production applications.

Plasmadyne pro overcomes these manufacturing and decorating challenges.

Plasma atmospheric system for many different substrates mr ap 4 6 8 10k igbt.

Plasma3 represents a new generation of surface treatment technology.

The atmospheric plasma robot is available with a range of xyz travel options from 200mm square to 500mm square and up to 150mm of z motion.

The system can be used as.

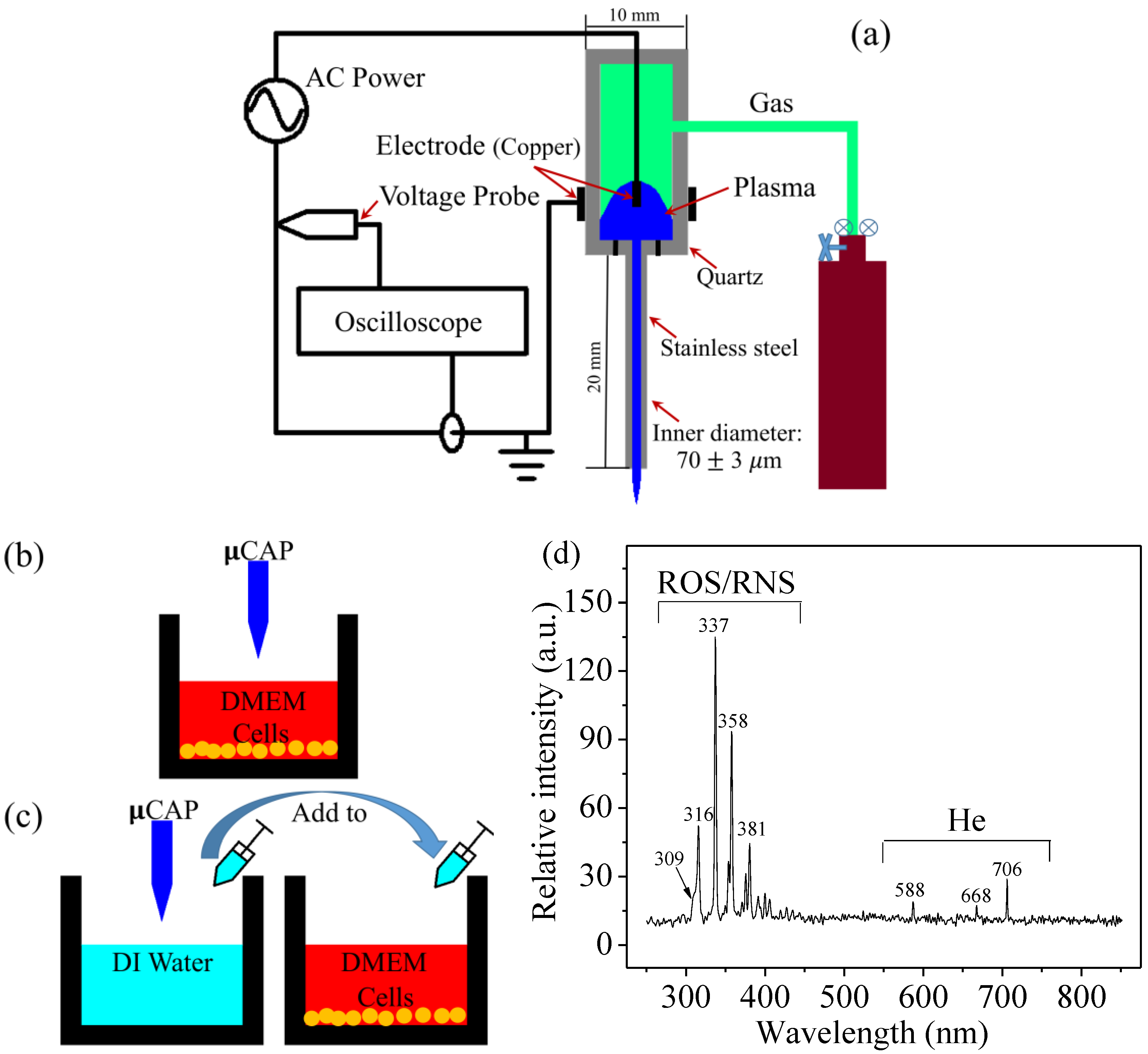

It allows plasmas to be sustained at atmospheric pressure in a way that permits the surface treatment of polymers and other substrates.

It can be configured to work with a variety of feeding systems including continuous web.

Atmospheric plasma robot system for surface treatment the atmospheric plasma robot system is a 3 axis desktop or cart mounted unit for automation of the plasma surface treatment process.

It s portable fast and effective on any coated surface.

Surfaceprep xd atmospheric plasma system.

The atmospheric plasma torch technology is now also available in a fully integrated and automated system.

Discover breakthrough technology for coating removal.

Using different types of gas the plasma obtained will give the substrate the required characteristics for any specific application.

Intrface technologies provides advanced material interface solutions using non contact atmospheric plasma treatment systems to clean activate functionalize or etch virtually any material surface.

The versatility of this unit allows for use in fully integrated robotic cells as a standalone unit or most any production line.

Tantec s new plasmatec x atmospheric plasma treatment system is built around the concept of a high voltage dc plasma discharge in atmospheric air.