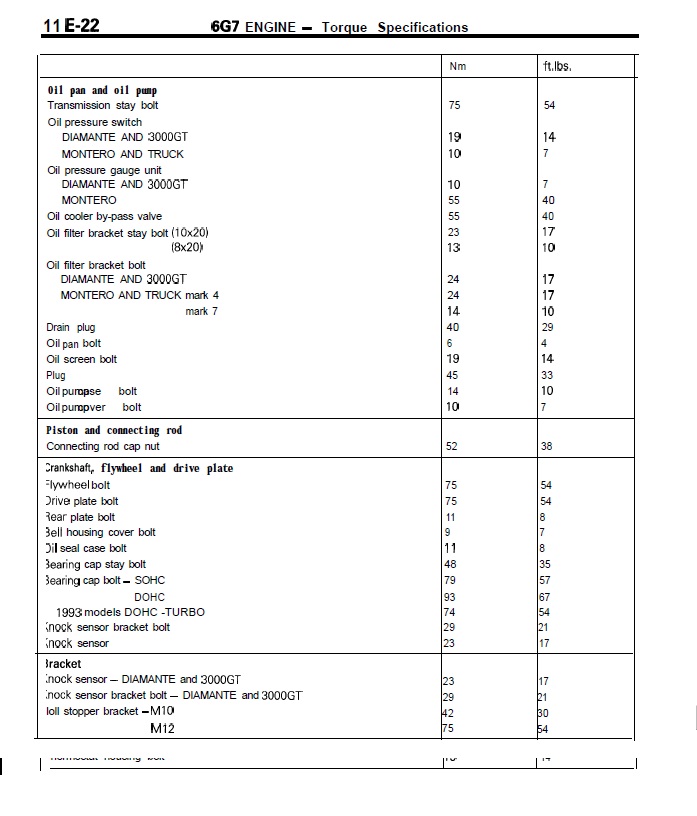

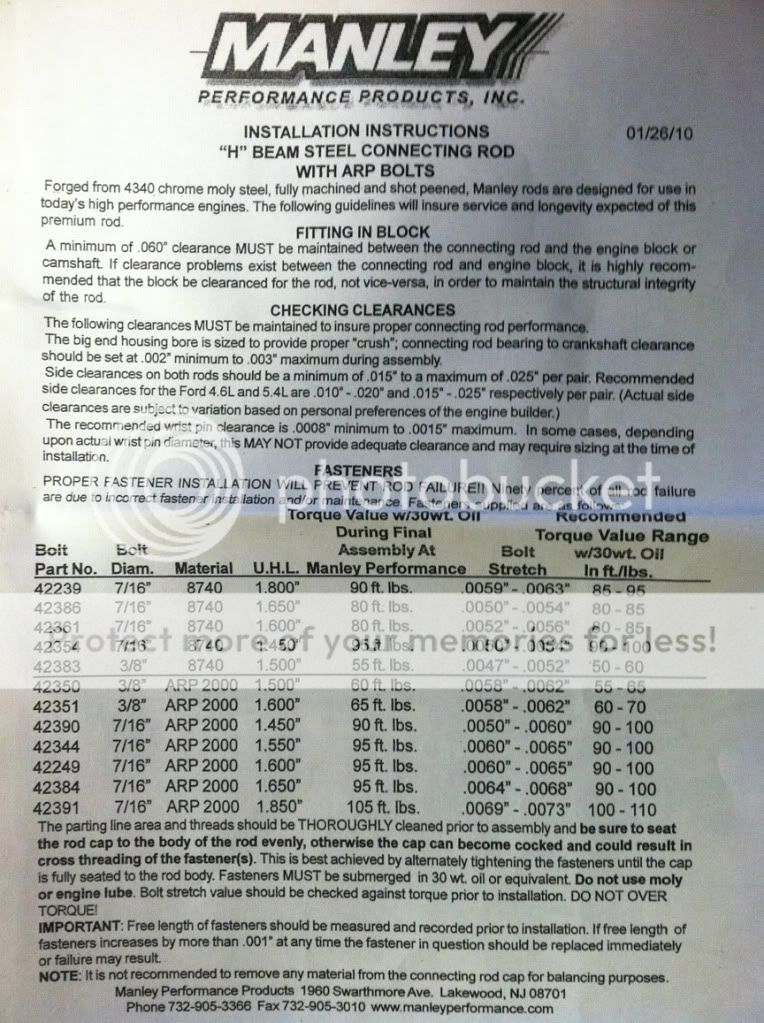

If you have an aftermarket connecting rod with an arp bolt please use the chart below to contact the rod manufacturer for the stretch torque value.

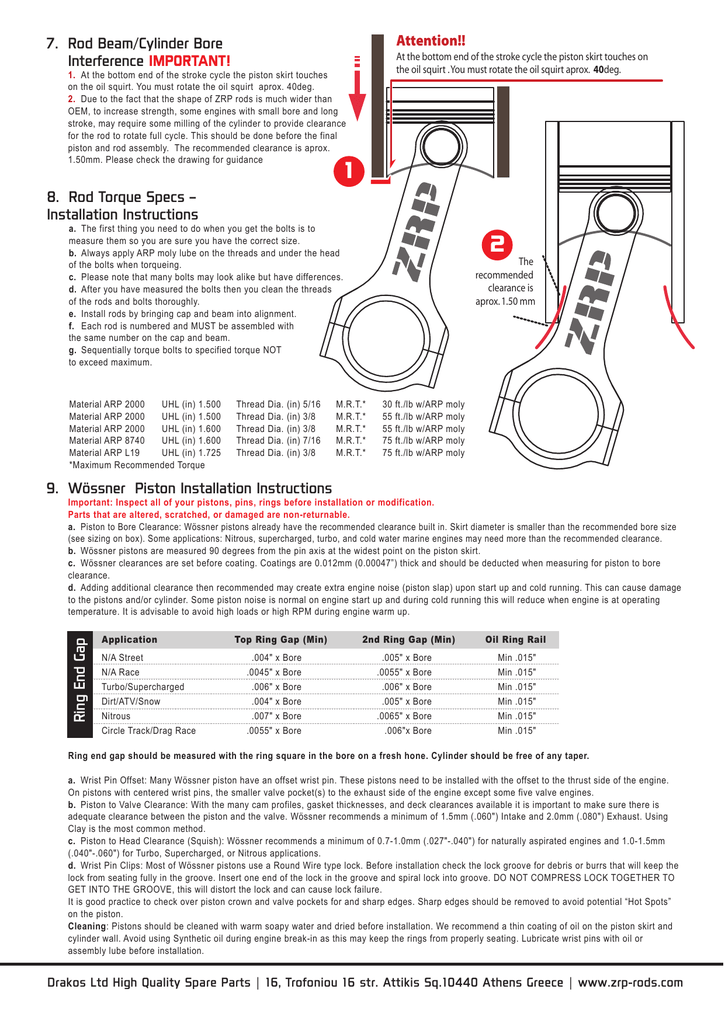

Arp 2000 rod bolts torque specs.

30ft lbs 360in lbs 60ft lbs 720in lbs then finally.

Eagle has arp custom make bolts to our specifications.

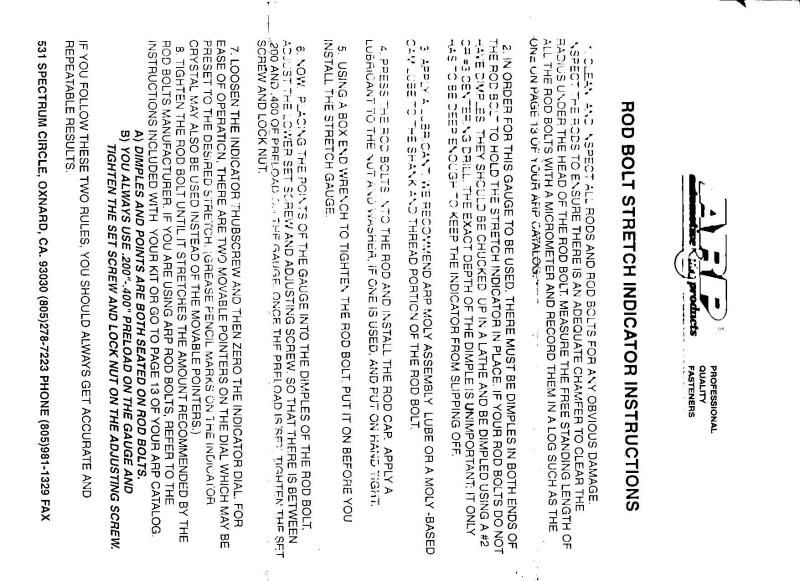

To achieve optimum accuracy always use arp ultra torque fastener assembly lubricant whenever possible.

22ft lbs 264in lbs then to 61ft lbs 732in lbs final spec 90 93 teg b16 s buy parts arp head bolts all b series clean block thread holes till dry lube top nut threads only with 10w30 or arp molly lube then use a 5 16 allen key to torque bolt studs to 10ft lbs into the block torque arp nuts in steps.

The torque values represented here are intended to be for general information only not for specific installations.

Listed here are the general torque recommendations for most arp fasteners.

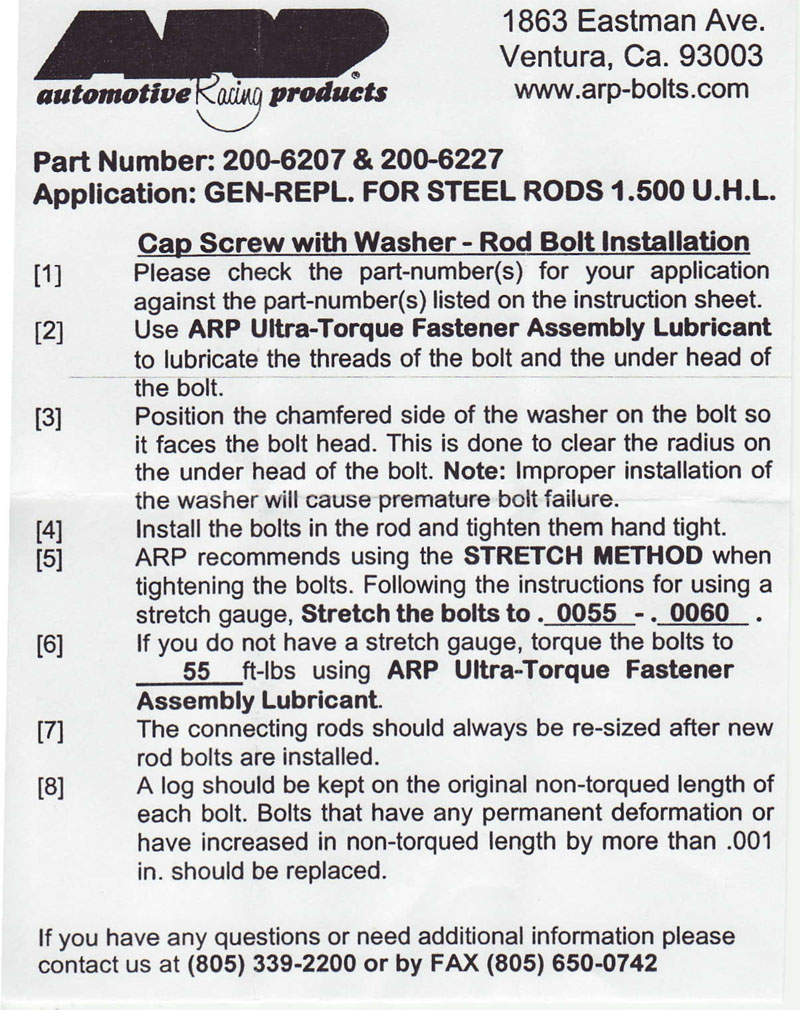

2 apply arp molylube to the threads and under the head of each bolt.

Here is a diagram of some important bolt identifying features.

Click here to download a printable rod bolt stretch monitoring chart.

Want to check a torque or stretch value.

Lost your kit instructions.

So when you pull a some l19 bolt to 006 you are doing because it creates the maximum clamping force for that bolt even if it waaaaay above the rods ability to handle that forces required to exceed that clamping force and possibly racked the rod bore all to hell in the process.

Do not use torque specs for off the shelf arp bolts.

Apply arp ultra torque to fastener threads and the underhead of the bolt or underside of the nut.

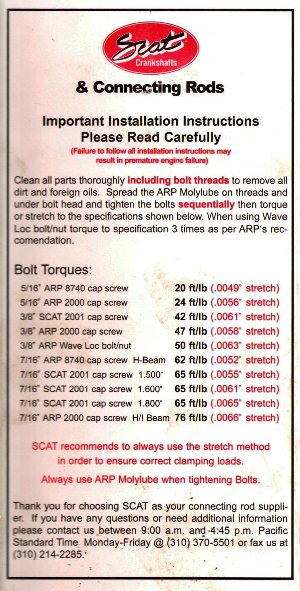

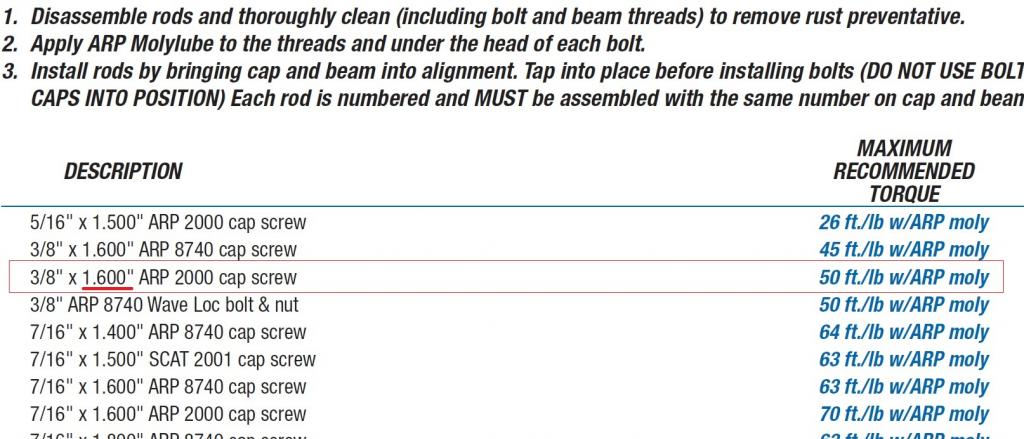

Ad performance scat rod bolt torque specifications rod torque specsimportant installation instructions1 disassemble rods and thoroughly clean including bolt and beam threads to remove rust preventative.

Recommended torque is equal 75 of the fastener s yield strength.

Use torque wrench to install fastener to the torque value from the chart below.

Do not use torque specs for off the shelf arp bolts.

3 install rods by bringing cap and beam into alignment.

Enter your kit number in the field below and click submit important.

This is information that you can never find when you need it so here is a table for the arp head studs main studs and rod bolts torque specifcations and stretch specs.

Install fastener hand tight.

Here is a diagram of some important bolt identifying features.

Simply read down to the correct fastener.

The calculation of those values is solely up to the rod manufacturer.

If you do employ the torque angle method it s best to begin calibrating rotation from some small measured torque rather than the first point of contact with the work face.